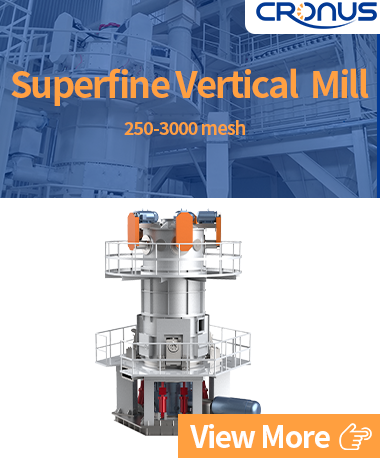

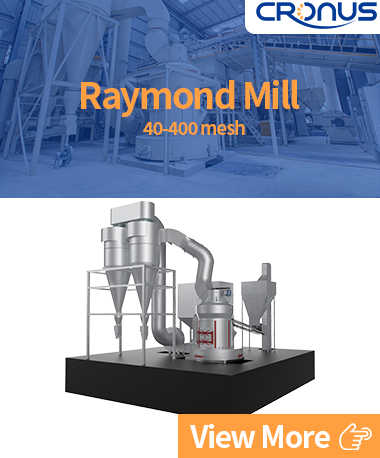

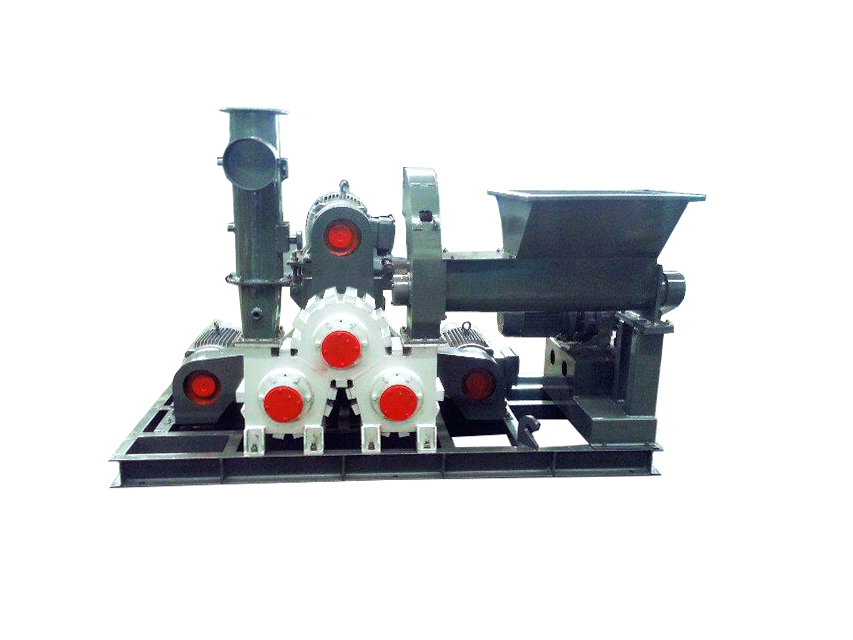

Pictures of 325 mesh calcium carbonate powder production line

Project Overview of 325 mesh calcium carbonate powder production line

325-mesh calcium carbonate powder is a common inorganic powder material. Due to its moderate particle size (about 44 microns), low cost, and good physical and chemical properties, it is widely used in many industries. The following are its main application categories and detailed descriptions:

I. Construction and Building Materials Industry

- Paints and latex paints: Added as a filler to paints, it can increase the volume of the paint, reduce costs, improve the paint’s brushability, wear resistance, and hiding power, and also enhance the impact resistance and weather resistance of the coating.

- Putty powder: It is one of the main fillers for putty, which can improve the hardness, flatness, and workability of putty, and reduce shrinkage and cracking.

- Cement and concrete: Appropriate additions can adjust the setting time of concrete, increase its strength, reduce production costs, and improve the workability of concrete.

- Wall materials: Such as aerated concrete blocks and lightweight partition boards, adding it can improve the compactness and compressive performance of the materials.

II. Plastics and Rubber Industry

- Plastic filling: Used as a filler in plastics such as polyethylene, polypropylene, and polyvinyl chloride, it can increase the rigidity, hardness, and dimensional stability of plastics, reduce the shrinkage rate, and at the same time reduce the amount of resin used and lower production costs. For example, it is widely used in plastic pipes, plastic films, plastic toys, and other products.

- Rubber reinforcement: Used in natural rubber and synthetic rubber, it can improve the wear resistance, tear resistance, and tensile strength of rubber products, reduce the heat generation and shrinkage of rubber. It is commonly used in rubber products such as tires, hoses, tapes, and sealing rings.

III. Paper Industry

- Paper filler: Adding 325-mesh calcium carbonate powder during papermaking can improve the whiteness, opacity, and smoothness of paper, enhance the printing performance of paper, and reduce the amount of pulp used, saving wood resources and lowering production costs. It is often used in cultural paper, packaging paper, etc.

- Coating processing: In the paper coating process, as a pigment component, it can make the coating more uniform and improve the gloss and surface strength of the paper.

IV. Coatings and Inks Industry

- Water-based coatings: In addition to architectural coatings, it is also used as fillers in industrial water-based coatings to enhance the adhesion and anti-corrosion performance of the coatings.

- Inks: In ink production, it can adjust the viscosity and fluidity of the ink, improve the coloring power and printing adaptability of the ink, and reduce production costs. It is suitable for offset printing inks, gravure inks, etc.

V. Other Industries

- Feed additives: Appropriate additions to livestock and poultry feed can provide calcium elements for animals, promote bone development, and improve the palatability and digestibility of the feed.

- Food industry: 325-mesh calcium carbonate powder that meets food-grade standards can be used as a food additive in products such as flour, pastries, and beverages, as a calcium fortifier or anti-caking agent.

- Ceramic industry: Adding it to ceramic blanks and glazes can reduce the firing temperature and improve the compactness and mechanical properties of ceramics.

In conclusion, 325-mesh calcium carbonate powder, with its excellent performance and economy, plays an important role as a filling, reinforcing, or function-regulating agent in many fields, and is an indispensable basic raw material in industrial production. Different industries may have different requirements for their purity, whiteness, and other indicators. In practical applications, the corresponding grade of products should be selected according to specific needs.