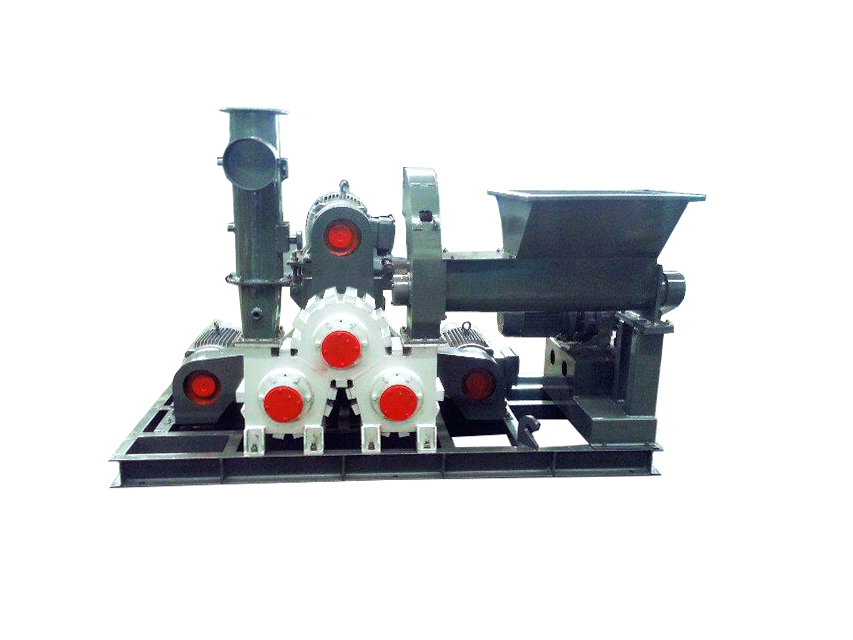

Recently, our company’s pendulum raymond mill has been under intense installation in Taiyuan, Shanxi Province.

Pendulum Raymond Mill Project Details

processing materail:attapulgite

final fineness:150 mesh D95

capacity:2 TPH

pendulum raymond mill model:CRRM1280

After more than half a month of hard work, our installation team overcame various difficulties and successfully completed the equipment installation task. We also provided detailed training to the client’s operators, covering the operation sequence of the equipment, operation precautions, as well as the maintenance and care of the pendulum raymond mill.

After the trial operation of the pendulum Raymond mill, the equipment of our company performed well, operated stably, and maintained stable product quality, which won unanimous recognition from the customers. This customer has also become a classic case of our company’s Pendulum Raymond Mill processing attapulgite.

What is Attapulgite?

Attapulgite, also known as palygorskite, is a kind of clay mineral. It is primarily composed of hydrated magnesium aluminum silicate, characterized by a unique fibrous or needle-like crystal structure.

- Its chemical formula is generally expressed as: (Mg, Al)₂Si₄O₁₀(OH)·4H₂O.

- It has excellent properties such as high specific surface area, strong adsorption capacity, good colloidal properties and cation exchange capacity.

- It is widely used in various fields such as agriculture, industry, environmental protection, and medicine. For example, in agriculture, it can be used as a soil conditioner and pesticide carrier; in industry, it can be used as a thickener, catalyst carrier, and filter aid.

The application of ultrafine attapulgite powder:

The core advantage of ultra-fine attapulgite powder lies in the performance upgrade brought by “ultra-fine crushing”. Its role essentially expands the material’s functions in adsorption, modification, and carrier applications, etc., by optimizing surface properties and microstructures. In practical applications, surface modification (such as coupling agent treatment, organic modification) is often carried out according to the needs of different fields to further enhance its compatibility and specific functions with other substances.

ultrafine attapulgite powder

1. In adsorption and purification fields

- Wastewater treatment: The high specific surface area and porous structure of ultra-fine powder significantly enhance its adsorption capacity for heavy metal ions (such as Pb²⁺, Cd²⁺), organic pollutants (such as dyes, pesticides), and oily substances. It can be used as an efficient adsorbent for the purification of industrial wastewater and domestic sewage.

- Air purification: It can adsorb harmful gases (such as formaldehyde, benzene) and odor molecules in the air, and is often used to prepare air purification materials (such as adsorbents, filter materials).

- Soil remediation: By adsorbing heavy metals and organic pollutants in the soil, it reduces their bioavailability and improves the soil environment.

2. As industrial fillers and additives

- Polymer material modification: As a filler added to plastics, rubber, and coatings, it can improve the mechanical properties (such as strength, toughness), heat resistance, and dimensional stability of materials, while enhancing processing fluidity (such as reducing melt viscosity).

- Inks and coatings: Using its colloidal properties and suspension stability as a thickener and anti-sedimentation agent to prevent pigment precipitation and improve the uniformity and gloss of coatings.

- Ceramics and refractory materials: The refined particles can optimize the forming properties of the green body and improve the density and mechanical strength of ceramic products.

3. In agriculture and ecology fields

- Soil improvement: The porous structure of ultra-fine powder can improve the water and fertilizer retention capacity of soil, regulate soil air permeability, and serve as a carrier to adsorb fertilizers and pesticides for slow release, thereby increasing their utilization rate.

- Pesticide and fertilizer carrier: Its high adsorption capacity makes it an efficient carrier for loading pesticides, plant growth regulators, etc., reducing volatilization and loss and prolonging the action time.

- Feed additive: As a mineral additive in feed, it adsorbs mycotoxins in feed, improves the intestinal environment of animals, and supplements minerals such as magnesium and silicon.

4. In energy and catalysis fields

- Catalyst carrier: Its high specific surface area and stable crystal structure make it suitable for loading metal catalysts (such as Fe, Cu, Ni, etc.), used in chemical reactions (such as hydrogenation, dehydrogenation, isomerization) and environmental protection catalysis (such as waste gas treatment).

- Auxiliary for energy storage materials: As an additive for electrode materials in lithium-ion batteries, it improves the conductivity and cycle stability of electrodes; or it is used to adsorb energy storage media (such as hydrogen, carbon dioxide).

5. In pharmaceutical and daily chemical fields

- Drug carrier: Using its adsorption and biocompatibility to load drugs for controlled release, or as a disintegrant and excipient for tablets.

- Cosmetic additive: Added to masks and lotions to adsorb skin oil and impurities, while using its colloidal properties to improve the skin feel and stability of products.

6. Other special applications

- Military and aerospace: As a filler for sealing materials and high-temperature-resistant coatings, or for preparing composite materials with radiation resistance and impact resistance.

- Paper industry: As a retention agent and filtration aid to improve paper strength and papermaking performance, while reducing fiber loss.