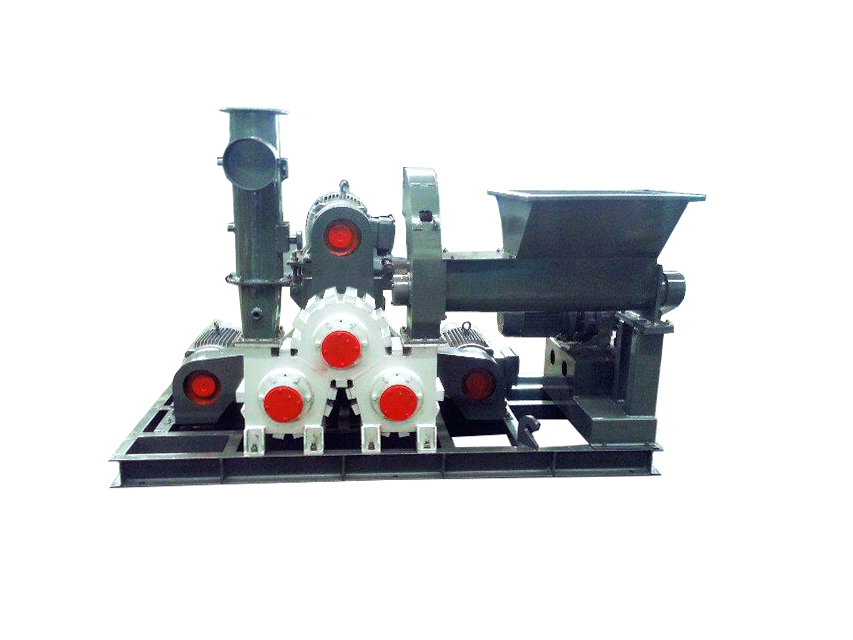

Why do we choose High-chromium alloy as the main material of grinding rollers and rings?

The main reason why high – chromium alloy is often used as the material for the grinding rolls and grinding rings of flour mills is that high – chromium alloy has many advantages, such as high hardness, good wear – resistance, strong impact – resistance, etc., which can well meet the working requirements of flour mills. The specific reasons are as follows:

High Hardness

High-chromium alloy contains a large amount of chromium, which can form hard carbides. These carbides are uniformly distributed in the matrix, making the material very high hardness. Its hardness can usually reach about HRC50-65. This high hardness can effectively resist the cutting and wear of the material on the surface of the grinding roll and grinding ring during the grinding process, maintain the dimensional accuracy and surface quality of the parts, and prolong their service life.

Good Wear – resistance

The high-hardness characteristic endows the high-chromium alloy with excellent wear resistance. When the flour mill is working, the grinding rolls and grinding rings will be in repeated extrusion, grinding and friction with various hard materials, and the wear is very serious. The wear resistance of high-chromium alloy is much higher than that of ordinary alloy steel and cast iron. It can effectively reduce the wear amount in long-term work, reduce the replacement frequency, so as to improve the production efficiency and reduce the maintenance cost.

High Strength and Toughness

High-chromium alloy has a certain strength and toughness while having high hardness. Although its toughness is slightly lower than that of high-manganese steel and other materials, through reasonable composition design and heat-treatment process, it can ensure that it will not be easily broken or crushed when subjected to a certain impact load, thus ensuring the normal operation of the flour mill. For example, in some large-scale flour mills, by optimizing the formula of high-chromium alloy, it can bear greater grinding pressure and impact, and at the same time, maintain good wear resistance.

Corrosion and Oxidation Resistance

The presence of the chromium element makes high-chromium alloys have good corrosion and oxidation resistance. In the grinding process, the grinding rolls and grinding rings may come into contact with some corrosive substances or work in a high-temperature environment. The corrosion and oxidation resistance of high-chromium alloy can prevent its surface from being corroded and oxidized, and avoid the decrease of material performance and the aggravation of wear caused by corrosion and oxidation, further prolonging its service life.

High Cost – effectiveness

Although the initial cost of high-chromium alloy may be slightly higher than that of some common materials, its excellent performance can greatly prolong the service life of the grinding rolls and grinding rings, reduce the replacement times and downtime, and reduce the maintenance and repair costs. In the long run, the use of high-chromium alloy materials can bring better economic benefits to enterprises and improve the stability and continuity of production.

In addition, through some advanced production processes, such as composite casting, the performance of high-chromium alloy can be further optimized to make it better meet the working requirements of flour mills. However, in practical applications, according to the specific working conditions and material characteristics, other materials or composite materials will also be comprehensively considered to achieve the best use effect.

How many times is the wear resistance of high-chromium alloy that of ordinary steel?

The wear resistance of high-chromium alloy is much better than that of ordinary steel. According to relevant data, its wear-resistance is usually 20 to 30 times or more than that of ordinary steel.

For example, in some wear tests, it is found that the wear-resistance of the high-chromium alloy wear-resistant layer can reach 20 to 25 times that of ordinary steel. The wear-resistance of high-chromium alloy composite wear-resistant steel plates can also reach 20 to 30 times or more than that of ordinary steel plates. There is also data showing that the wear-resistance of high-chromium alloy is more than 20 times that of ordinary steel.

However, the specific multiple will be affected by various factors, such as the composition, manufacturing process and heat-treatment method of high-chromium alloy, the type of ordinary steel, and the conditions and working conditions of the wear test. Therefore, the actual multiple may vary.