How to choose a suitable Raymond mill?

In industrial production, the Raymond mill serves as a crucial grinding equipment and is widely used in various fields such as mining, metallurgy, and building materials. The performance of the mill directly impacts production efficiency and product quality. Therefore, when purchasing a Raymond mill, it is essential to pay close attention to the following key details.

- Production Capacity and Particle Size Requirements

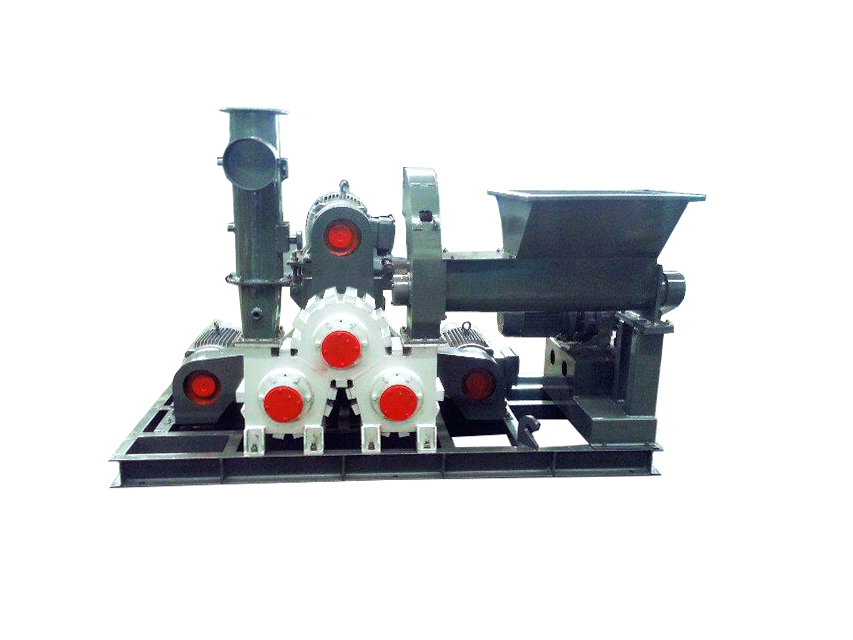

Different production needs impose varying requirements on the production capacity and finished particle size of Raymond mills. First, it is essential to accurately estimate the required grinding output based on your production scale to ensure the equipment’s capacity aligns with your needs. Additionally, the particle size standard of the product must be clearly defined, as Raymond mills can achieve different grinding fineness by adjusting various components. For example, in ore processing, stricter particle size requirements are typically necessary. The appropriate particle size range should be determined based on the characteristics of the ore and subsequent processing requirements, thereby selecting a mill model that meets these specifications. - Equipment Quality and Material

Equipment quality is crucial for ensuring long-term stable operation. High-quality Raymond mills are typically manufactured from high-strength steel, with the material of key components such as the main unit, analyzer, and fan determining the equipment’s durability and wear resistance. When evaluating equipment, attention should be paid to whether the main unit’s structural design is reasonable and whether it facilitates installation, maintenance, and repair. For wear parts, such as rollers and rings, it is important to understand the wear resistance of their materials. High-quality wear parts can effectively reduce maintenance frequency and production costs. - Energy Consumption and Environmental Performance

In the current context of promoting energy conservation and emission reduction, the energy consumption and environmental performance of equipment cannot be overlooked. Efficient and energy-saving Raymond mills can significantly reduce a company’s energy costs. When purchasing, it is necessary to review the equipment’s energy consumption indicators and compare differences across brands and models. Meanwhile, as environmental regulations become increasingly stringent, it is essential to ensure the mill has good environmental performance, such as being equipped with advanced dust removal devices to minimize dust emissions, avoid polluting the production environment, and comply with relevant national environmental standards. - Brand and After-Sales Service

Choosing a well-known brand for a Raymond mill ensures product quality and performance. Reputable brands typically possess mature production processes, strict quality control systems, and extensive market experience.