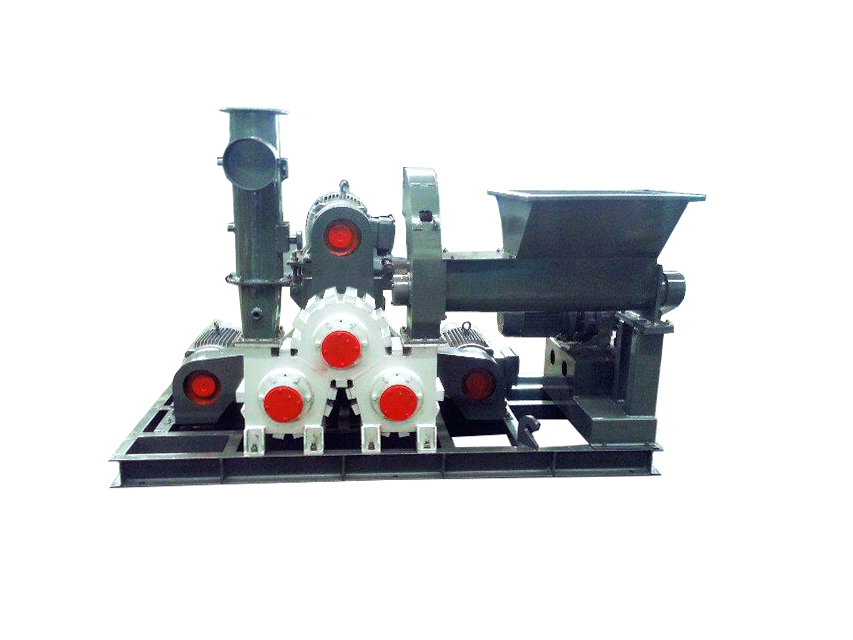

The Raymond mill is a commonly used ultra-fine grinding equipment for processing ore into powder. This equipment crushes materials through the grinding rollers pressing against the grinding ring, achieving the desired fineness and output with the combined action of a fan and an analyzer. The entire Raymond mill system adopts a positive-negative pressure circulating air design, allowing the adjustment of airflow to control fineness and output. Recently, some users have inquired about how to address the issue of air duct blockages during daily Raymond mill operations. The following section analyzes the causes of this problem and provides solutions, hoping to assist users in their daily Raymond mill production.

Excessive feeding

The feeding of a Raymond mill should be uniform and at a consistent rate—neither too much nor too little. Excessive feeding can easily lead to blockages, while insufficient feeding may cause iron-to-iron grinding, resulting in loud noise. When the feed is too heavy, the main unit of the Raymond mill is prone to clogging, and the excess material will be blown into the surrounding air ducts. Over time, a significant amount of material can accumulate around the air ducts.

Air intake at the discharge port

The Raymond mill adopts a positive-negative pressure circulating air design. If air enters through the discharge outlet, it can carry a small amount of finished product from the collector back into the main unit, dispersing it around the air ducts. Prolonged operation under such conditions may lead to blockages in the air ducts. During daily production, attention should be paid to the counterweight adjustment of the Raymond mill’s feeder to prevent air from entering through the inlet.

Dust collector malfunction

The primary functions of the dust collector for a Raymond mill are to ensure air permeability, dissipate heat, and remove dust. The filter bags in the dust collector are prone to clogging after prolonged use, so they should be replaced or shaken periodically to maintain good air permeability. If this part becomes blocked, it can cause the main unit of the Raymond mill to overheat, leading to abnormal operation, and may also result in excess material accumulating around the air ducts.

Air leakage in the negative-pressure pipeline

The Raymond mill operates with a circulating air system and a positive-negative pressure design. If there is an air leak in the positive pressure area, powder will be ejected outward, which can be visually detected and promptly addressed by sealing it tightly. However, if there is an air leak in the negative pressure area—where the pipeline draws air inward—the issue is invisible to the naked eye. This can lead to host machine blockages, affecting fineness and production output, and over time may also clog the air ducts.

The solution is simple: shut down both the host machine and the analyzer, then run only the fan. Carefully inspect the system section by section to locate the air leak and seal it properly.