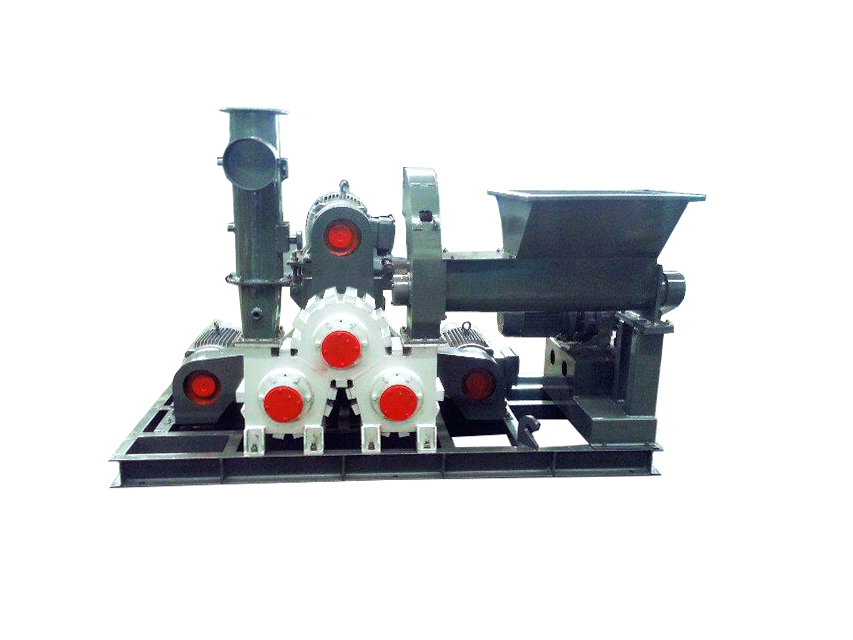

The Raymond grinding mill is one of the common equipment in the grinding production line. Due to its efficient and energy-saving features, it has won the favor of a large number of users. It can process various mineral materials quickly and with high quality, which is inseparable from its precisely designed core components. So, what are the main components of the Raymond grinding mill? Below, we will briefly introduce them for you:

Shovel

During the operation of the Raymond grinding machine, the curved scraper plays a crucial role. It continuously scoops up the materials and precisely transports them to the gap between the grinding rolls and the grinding rings. Compared to traditional grinding equipment, the scraper of the Raymond grinding machine adopts a unique curved design. This innovation not only increases the material carrying capacity but also significantly improves the production efficiency. It is worth noting that the number of scrapers is matched with the grinding rolls, and both are determined by the model of the grinding machine, ensuring the coordinated operation between them.

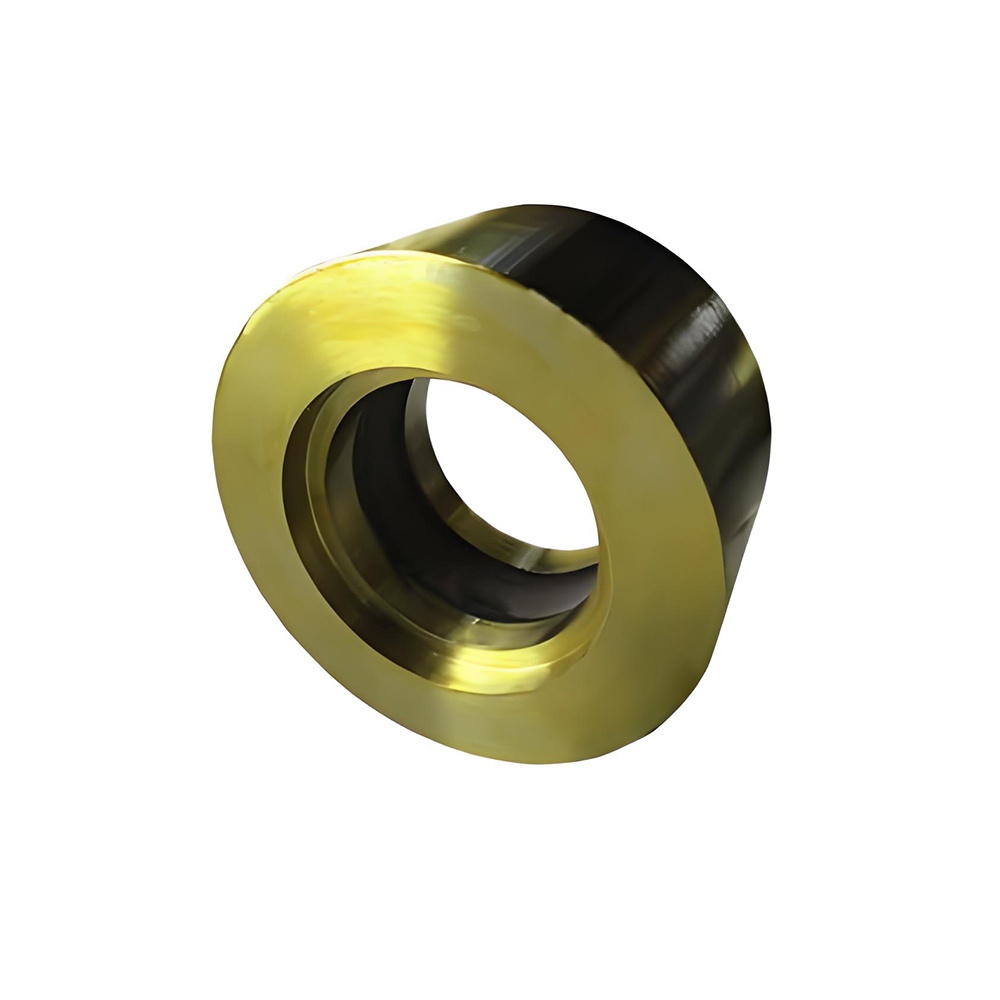

Grinding rollers and grinding rings

The grinding rollers and grinding rings of the Raymond mill, as its main grinding components, are usually meticulously cast from high manganese steel wear-resistant material. During the grinding process of the materials, these two major components complete the grinding task through the pressing action. However, long-term operation inevitably leads to a certain degree of wear. Therefore, in the powder production process, we need to closely monitor the wear condition of the grinding rollers and grinding rings and promptly carry out maintenance and repair work. For severely worn components, they should be replaced in time to ensure that the powder grinding quality and production efficiency are not affected.

Analyzing the machine and the fan blades

The analyzer and the fan blades are the key components in a Raymond grinding mill that ensure the grinding rate and quality of the powder. They perform a fine screening of the materials by rotating to select the fine particles. However, as the grinding process continues, these components will gradually wear out. Especially the fan blades, if they are worn or rotate abnormally, will directly affect the air volume transmission of the entire machine. And the wear of the analyzer’s blades may lead to a significant decline in the powder quality. Therefore, we must attach great importance to the regular maintenance and replacement of the analyzer and fan blades to ensure the smooth operation of the grinding process.