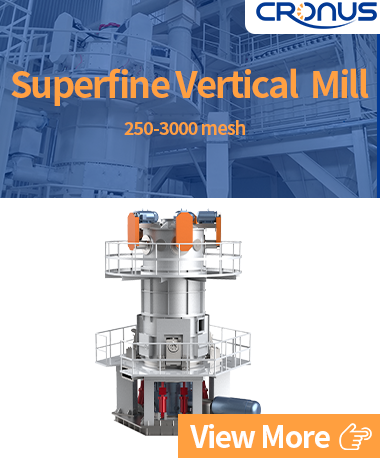

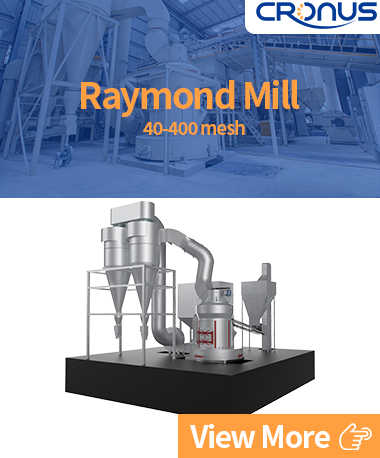

Recently, Cronus’s flagship equipment — the 4R3220 Raymond Mill — successfully completed loading and departed from the Port of Shanghai, heading to the non-metallic mineral processing project site in Nigeria. As a core equipment tailored for global mid-to-high-end powder processing scenarios, the Cronus 4R3220 Raymond Mill, with its core advantages of high efficiency, energy saving, wide adaptability and stable operation, coupled with the strong support of Cronus’s customized overseas after-sales service system, will provide a one-stop powder processing solution for Nigerian customers, helping upgrade local construction materials, chemical and other industries, and continuously enhancing Cronus’s brand reputation in the African market.

Strong Product Strength Meets Nigeria’s Diverse Processing Needs

Nigeria is rich in non-metallic mineral resources, with considerable reserves of limestone, gypsum, barite, etc. However, there is an urgent demand for efficient, energy-saving, and highly adaptable powder processing equipment in the local market. The Cronus 4R3220 Raymond Mill has been customized and optimized for the working conditions of the African market, achieving multiple breakthroughs in core performance and perfectly meeting local processing needs.

Outstanding efficiency and energy-saving advantages, remarkable cost reduction, and efficiency improvement results. On the basis of traditional Raymond Mills, this equipment optimizes the grinding structure, increasing the height of grinding rollers and rings to 200mm, which expands the grinding area by 25%. Equipped with a 45kW high-power blower, its production capacity is 30% higher than that of traditional equipment of the same model, capable of meeting the powder processing requirements of 1-6 tons per hour with adjustable fineness of 80-400 meshes. Meanwhile, adopting the optimized air circulation design and low-power motor configuration, the energy consumption per unit of powder processing is as low as 20-30kW·h/t, saving 30%-40% of electricity costs compared with the industry average, and significantly reducing customers’ long-term operating costs.

Wide adaptability and stable operation, handling complex materials with ease. The equipment can accurately process non-flammable and non-explosive minerals with Mohs hardness ≤9.3 and humidity ≤6%, perfectly covering mainstream non-metallic mineral processing scenarios in Nigeria. The core grinding components are made of high-chromium alloy, which has been specially quenched to greatly improve wear resistance and impact resistance. Combined with the multi-seal structure design, it can effectively resist the erosion of dust and humid environments, ensuring strong stability of continuous operation with an uptime rate of over 95%. In addition, the fineness of finished products is precisely controlled by an intelligent analyzer, featuring high uniformity, which can meet the strict requirements for powder quality in construction materials, chemical industry, metallurgy, and other fields.

Intelligent and convenient operation, reducing labor dependence. The equipment is equipped with a full set of intelligent electrical control systems, with a simple and intuitive operation interface, enabling one-key start/stop, fineness adjustment, real-time monitoring of operating parameter,s and other functions, which is easy for new operators to master quickly. At the same time, the equipment adopts a humanized structural design, facilitating the replacement of wearing parts and minimizing daily maintenance workload. This is well-suited to the current situation of scarce professional operation talents in Nigeria, further helping customers save labor costs.

Customized Overseas Service System, Whole-Process Escort for Efficient Project Implementation

In response to the particularity of cross-border projects, Cronus has prepared a full-process customized after-sales service plan for this Nigerian order, building a “one-stop” service closed loop from pre-sales training to after-sales operation and maintenance, completely solving customers’ worries.

Precise pre-sales empowerment, laying a solid operational foundation. Before the equipment shipment, Cronus invited the technical team of the Nigerian customer to its domestic production base for a 15-day special training. Through a combination of “workshop practice + theoretical teaching + case explanation”, the training covers all aspects, including equipment assembly and commissioning, core component maintenance, common fault handling, and safety operation procedures. Meanwhile, a full set of Chinese-English bilingual operation manuals, maintenance videos, and toolkits is provided to ensure that the customer’s team fully masters the equipment operation and maintenance skills.

On-site in-sales support, ensuring rapid commissioning. Cronus dispatched 2 senior after-sales engineers to the Nigerian project site simultaneously, providing 2-month on-site service to guide the entire process of equipment unloading, positioning and installation, commissioning and operation, ensuring that the equipment is put into production within 30 days after arrival. The engineers will also optimize the equipment operating parameters according to local raw material characteristics and processing needs, maximizing equipment performance to achieve both production capacity and quality standards.

Long-term after-sales guarantee, solving operation and maintenance problems. A three-dimensional after-sales service system of “24-hour hotline + online real-time response + local spare parts support” has been established. Customers can contact us for help at any time through the exclusive service WeChat group and 24-hour technical hotline. The technical team promises to respond within 2 hours and provide solutions within 24 hours. Meanwhile, Cronus has pre-stocked core-wearing parts in areas around Nigeria to ensure that urgently needed spare parts are delivered to the site within 48 hours, significantly reducing equipment downtime. For the long-term operation needs of the project, value-added services such as annual on-site maintenance and technical upgrading are also provided to ensure the stable operation of the equipment throughout the whole process.

Deepening Presence in the African Market, Building Global Competitiveness with Quality and Service

The shipment of the Cronus 4R3220 Raymond Mill to Nigeria is not the brand’s first layout in the African market. Previously, Cronus series grinding equipment has successfully served mineral processing projects in many African countries such as Nigeria, Guinea, and South Africa, gaining a good market reputation with reliable product quality and improved service system.

In the future, Cronus will continue to focus on overseas market demand, optimize product design according to the working conditions of different regions, continuously improve the global after-sales service network, and build core competitiveness of “high-quality equipment + customized services”. At the same time, it will deepen cooperation with local partners in Africa to provide more targeted solutions for African mineral resource development and industrial upgrading, bringing Chinese intelligent manufacturing to more global customers.

It is reported that the shipped Cronus 4R3220 Raymond Mill is expected to arrive at the Port of Lagos, Nigeria in mid-next month. The after-sales engineer team is ready to depart simultaneously to ensure the rapid commissioning of the equipment and help the customer realize capacity release and benefit improvement at an early date.