what is rCB production line ?

The RCB production lines are primarily represented by the recycled carbon black (rCB) production line and the regenerative combustion (RCB) production line, which serve the fields of resource recycling and industrial energy conservation, respectively. The appropriate type must be selected based on the application scenario: the rCB production line is suitable for waste tire recycling, while the RCB regenerative combustion production line is ideal for industrial heating energy savings.

The main equipment used in the RCB production line

Regarding the tire pyrolysis equipment

Tire pyrolysis equipment is a complete system that decomposes waste tires under anaerobic/deficient-oxygen conditions and at high temperatures of 500-800°C into pyrolysis oil (40-50%), pyrolysis gas (10-15%), crude carbon black (30-35%), and steel wires (5-10%). This technology represents a key approach to achieving 100% resource utilization of “black pollution.” When combined with Cronus ultra-fine ring roller mills, crude carbon black can be further processed into high-value-added recycled carbon black (rCB), which can replace 10-30% of the amount of virgin carbon black used.

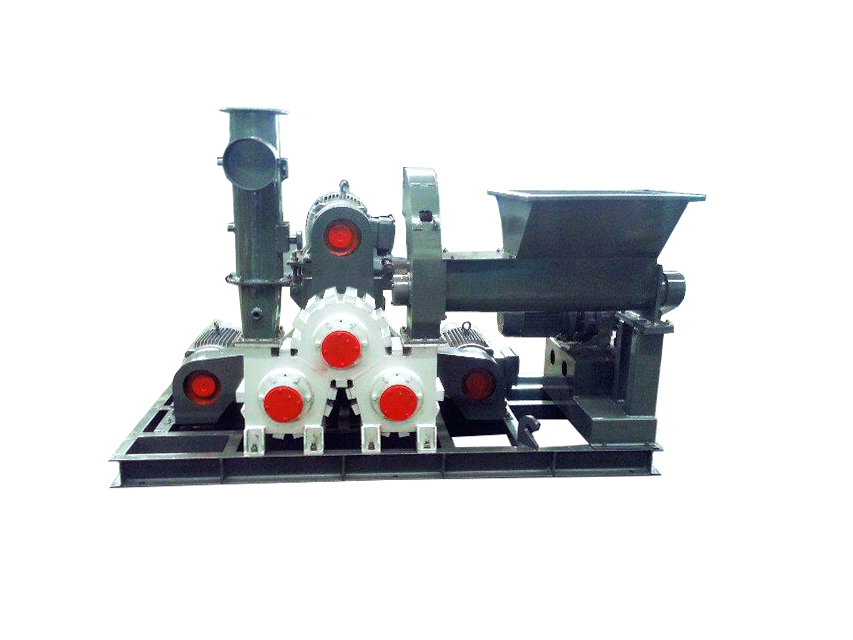

Regarding the carbon black grinder

Cronus Ultra-Fine Ring Mill: The core equipment used to grind coarse carbon black (300-500 mesh) to 300-3000 mesh. The resulting particles have a d50 size of 20-40μm, with a specific surface area increased to 40-90 m²/g. The DBP oil absorption value reaches 100-150 ml/100g. The performance of this carbon black is comparable to that of N550 grade natural carbon black.Now we have some clients in india who used for RCB plant.

capacity:0.8-10 TPH(depends on different model ultra-fine ring roller mill.

A complete RCB production line may include:

- Pretreatment System (Front-end Support)

- Shredders/ Crushers: Double-axis shear type, reducing tires to particles sized 0–20 mm while removing large impurities.

- Magnetic Separator: Strong magnets are used to separate steel wires, achieving a purity of up to 99.9%. This results in high recyclability value.

- Conveying Equipment: Sealed screw conveyors and bucket elevators prevent dust leakage and ensure safe operation.

- Pyrolysis Reaction System (Core Component)

- Pyrolysis Furnace:

– Continuous type: Rotary kiln design with an inclination of 3–5° and a rotation speed of 0.5–2 rpm. Internal baffles ensure uniform heating of the material.

– Heating Method: Gas/fuel/electric heating. Up to 80% of the pyrolysis gas can be reused, reducing operating costs.

– Material: High-temperature resistant alloy steel with fire-resistant lining, capable of withstanding temperatures of 1200°C. Service life exceeds 5 years.

– Feeding/Discharging Devices: Double-gate design for airtightness, maintaining a slight negative pressure (-50 to -100 Pa) to prevent air entry and potential explosions.

- Oil and Gas Treatment System (Product Collection)

- Cooling System: Coil or shell-and-tube condensers cool oil and gas to pyrolysis oil, with a recovery rate of ≥95%.

- Oil and Gas Separator: Separates light and heavy oils to improve product purity.

- Pyrolysis Gas Purification: Desulfurization and dust removal enable the gas to be reused as fuel, achieving energy self-sufficiency.

- Carbon Black Deep Processing System (Value-Adding Step)

- Cooler: Spiral water cooling system reduces the temperature of crude carbon black from 600°C to below 80°C.

- Cronus Ultra-fine Roller Mill: Core equipment that grinds crude carbon black (300–500 mesh) to 1000–3000 mesh. The resulting particles have a d50 size of 20–40 μm, a specific surface area of 40–90 m²/g, and a DBP oil absorption value of 100–150 ml/100 g. The performance is comparable to that of N550 grade natural carbon black.

- Classifier: Turbine-based precision grading ensures uniform particle size distribution, with a qualified rate of ≥98%.

- Modification Equipment: Surface activation treatment improves the compatibility of rCB with rubber, allowing its usage ratio to reach 30%.

- Granulation/Packaging: Improves fluidity for easy storage and transportation. Packaging size is 25 kg/bag.

- Environmental Protection System (Compliance Requirement)

- Smoke Purification: Bag filter dust removal, activated carbon adsorption, and denitrification. Dust emissions ≤10 mg/m³, NO₃ ≤50 mg/m³.

- VOC Treatment: Catalytic combustion (RCO) with a removal rate of ≥99%, ensuring compliance with emission standards.

The Customer of Cronus ultra-fine grinding machine for RCB applications

Cronus Ultra-Fine Ring Mill: The Performance Leader in Carbon Black Deep Processing

- Core Advantages:

◦ Ultra-fine grinding: Output particle size can be adjusted between 1,000 and 3,000 mesh, meeting the requirements of high-end rCB products.

◦ High efficiency and energy savings: Energy consumption is 40% lower than that of traditional ball mills, while production capacity increases by 50%.

◦ Precise particle sizing: Built-in turbine grading system ensures a CV value of ≤5%, resulting in consistent product quality.

◦ Wear-resistant and durable: Made of tungsten carbide, its service life is three times that of ordinary materials, reducing maintenance costs by 60%. - Perfect Integration with Pyrolysis Equipment:

◦ Suitable for feed particle sizes: Can process crude carbon black after pyrolysis directly (≤5mm) without additional crushing.

◯ Capacity matching: Single unit has a processing capacity of 1–5 tons per hour, suitable for pyrolysis lines producing 30–50 tons per day.

◯ Intelligent integration: Can be connected to the pyrolysis furnace’s DCS system for real-time adjustment of process parameters, enhancing product stability.

RCB grinding mill is being prepared ship to India