How to dolomite powder making plant using a pendulum mill?

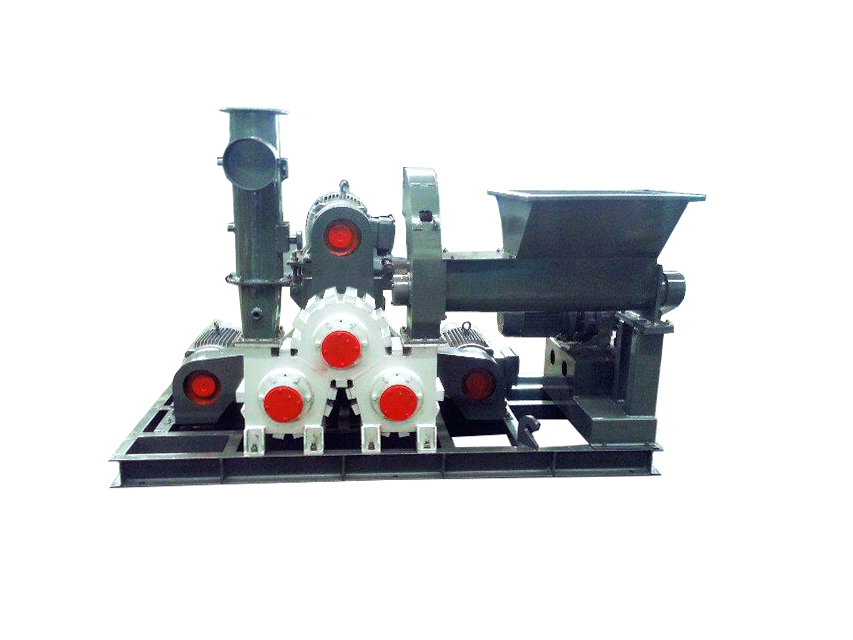

The pendulum mill is specialized equipment for processing mineral powder. This equipment has obvious performance advantages, mainly manifested as: the equipment has a relatively small floor area, low investment cost, and the fineness distribution of the processed mineral powder is wide, which can meet the different customers’ requirements for the fineness of mineral powder, and the particle shape of the mineral powder is relatively good, etc.

Due to these characteristics of the pendulum mill, it has been widely applied in the production of mineral powders, especially in the processing of non-metallic minerals such as limestone, calcite, and gypsum.

Today, we are going to introduce this mineral powder production enterprise located in Dongguan, Guangdong Province. It is currently the largest limestone powder producer in Guangdong Province. At present, it mainly processes 325-mesh and 1250-mesh limestone powder, and there are 20 production lines operating simultaneously. At present, a portion of the company’s coarse grinding process has adopted the pendulum mill produced by Cronus Company.

Project Overview of Dolomite Powder Making Plant:

Pictures of the dolomite powder making plant on-site display:

Additional Information

325 mesh dolomite powder application

325-mesh limestone powder, with its fine particle size and good reactivity, finds diverse practical applications. It is commonly used as a filler in industries like rubber, plastics, and paper-making, where it enhances product rigidity, reduces production costs, and improves processing performance without compromising basic material properties. In the construction sector, it serves as a key ingredient in cement and concrete formulations, helping adjust the setting time of cement and enhance the workability and durability of concrete mixtures. Additionally, it is utilized in agriculture as a soil amendment to neutralize acidic soils, supply calcium nutrients for crop growth, and optimize soil structure, thereby promoting better crop yields. It also has roles in water treatment, where it aids in adjusting water pH and removing impurities, and in the production of animal feed as a calcium supplement to support animal skeletal development.

1250 mesh dolomite powder application

1250-mesh limestone powder, characterized by its ultra-fine particle size, high whiteness, and excellent dispersion, is widely applied in fields demanding fine-quality materials. In the coating and ink industries, it acts as a functional filler to improve paint film smoothness, enhance color retention, and reduce the usage of expensive pigments, while also boosting the coating’s water resistance and weatherability. It is a key component in the production of high-grade paper (such as cultural paper and coated paper), where it refines paper surface texture, increases opacity, and enhances printability without affecting paper strength. Additionally, it is used in advanced plastic and rubber products to achieve better compatibility with polymers, thereby improving product surface finish, flexibility, and mechanical properties; it also finds use in cosmetics and pharmaceuticals as a mild abrasive or calcium source, thanks to its fine and non-irritating particles.

Processing equipment for different fineness of minerals:

You can get in touch with us via WhatsApp.