What are the uses of dolomite powder?

Dolomite Powder Manufacturing Plant Cost

Dolomite powder is a calcium-magnesium double carbonate powder (main component: CaMg(CO₃)₂) processed from dolomite through crushing and milling (by pendulum roller mills, ultra-fine mills and other equipment). Classified by fineness into ordinary powder (80-400 mesh) and ultra-fine powder (600-2500 mesh and above), it features dual activity of calcium and magnesium, excellent chemical stability, high cost performance, and adjustable fineness and purity as required. It has become a universal inorganic powder raw material in various industries and one of the mainstream non-metallic mineral materials processed by milling equipment.

Its applications cover core fields such as building materials, metallurgy, chemical industry, rubber and plastic fillers, agriculture, and environmental protection. Dolomite powder of different fineness corresponds to various high-end and conventional applications, which is compatible with the processing requirements of ultra-fine milling equipment. The core uses by field are as follows (key fineness requirements marked for matching milling equipment selection):

1. Building Materials Industry (the most mainstream application, mainly 80-600 mesh)

It is a basic raw material for building materials production. Its calcium and magnesium components can improve the strength and weather resistance of products and reduce production costs:

- Cement production: Used as a mineralizer/admixture to replace part of limestone, lower the cement calcination temperature, improve the early strength and sulfate erosion resistance of cement (80-200 mesh is commonly used).

- Glass/ceramics: Regulates the melt viscosity in glass production to improve glass transparency and toughness; supplements magnesium in ceramic blanks/glazes to reduce blank shrinkage and enhance glaze gloss (325-600 mesh is commonly used).

- New building materials: Serves as a filler in aerated concrete, gypsum boards and thermal insulation mortar to improve the compressive strength and water resistance of products (200-325 mesh is commonly used).

2. Metallurgical Industry (200-325 mesh, core features: fire resistance/flux properties)

Relying on the high fire resistance of magnesium oxide and the alkalinity of calcium, it is a key auxiliary material in the metallurgical industry:

- Refractories: Used to make alkali-resistant refractory bricks and linings for converters/electric furnaces in ferrous and non-ferrous metal smelting. It resists erosion by alkaline slag in furnaces and is a core raw material for the refractory layers of blast furnaces and cement rotary kilns.

- Metallurgical flux: Acts as a desulfurizer and dephosphorizer in iron and steel smelting to neutralize acidic impurities in furnaces, lower slag melting point and improve smelting efficiency. It can also be used for raw material purification in the magnesium smelting industry.

3. Chemical Industry (325-2500 mesh, covering both conventional and high-end applications)

Utilizing the chemical reactivity of calcium and magnesium, it serves as a chemical raw material and functional filler:

- Basic chemical raw materials: Processed through calcination and acidification to produce magnesium oxide, magnesium sulfate, magnesium carbonate, light calcium carbonate and other chemical products, which are widely used in daily chemical, pharmaceutical and food additive fields.

- High-end coatings/ink fillers: Ultra-fine dolomite powder (1250-2500 mesh) with high whiteness and uniform particle size can replace part of titanium dioxide as an extender pigment in coatings and inks, improving film hiding power and wear resistance, greatly reducing raw material costs and causing no heavy metal pollution.

4. Rubber and Plastic Fillers (800-2500 mesh ultra-fine powder, core for high-end applications)

As an important category of inorganic non-metallic fillers, it replaces part of talcum powder and calcium carbonate, meeting the modification requirements of plastics, rubber, and synthetic rubber. It is also a core high-value-added application processed by ultra-fine milling equipment:

- Serves as a functional filler added to PVC pipes, plastic films, rubber tires, and wire and cable materials to improve the rigidity, heat resistance, dimensional stabilit,y and anti-aging ability of products.

- Reduces the raw material cost of rubber and plastic products, and the powder has good compatibility with the substrate without affecting the processing and formability of products, making it a mainstream filler for rubber and plastic products used in home appliances, automobile,s and building materials.

5. Agricultural Field (80-200 mesh, easy-to-absorb type)

Focusing on calcium and magnesium nutrition supplements and soil improvement, it is green, environmentally friendly and low-cost:

- Soil amendment: Neutralizes soil acidity for acidic soil, supplements calcium and magnesium medium elements required by crops, improves soil fertility, suitable for the cultivation of fruits and vegetables, grain, tea and other crops, and reduces soil compaction.

- Feed additive: Serves as a calcium and magnesium supplement for livestock, poultry, and aquaculture, improving the skeletal development of livestock and poultry and the hardness of eggshells. With moderate fineness, it is easily digested and absorbed by animals, making it a low-cost inorganic additive in the feed industry.

6. Environmental Protection Field (325-600 mesh, alkaline adsorption/neutralization properties)

Relying on alkaline characteristics, it is used for wastewater and flue gas treatment as an economical raw material for environmental governance:

- Wastewater treatment: Neutralizes acidic wastewater, adsorbs fluoride ions and heavy metal ions (lead, cadmium, chromium, etc.) in wastewater, reduces wastewater acidity and pollutant concentration, suitable for wastewater treatment in mines, chemical industry and electroplating.

- Flue gas desulfurization: Replaces limestone as a desulfurizer for flue gas desulfurization in power plants and steel plants with high desulfurization efficiency. The desulfurization by-products can be recycled into magnesium sulfate to realize resource reuse.

7. Other Auxiliary Applications

- Paper industry: 325-800 mesh dolomite powder is used as paper filler and surface coating to improve paper whiteness, stiffness and smoothness, and reduce paper raw material costs.

- Daily chemical industry: Ultra-fine powder (2000 mesh and above) is used in facial cleansers, talcum powder and other products to replace part of talcum powder, improving skin feel without irritation.

- Road engineering: Serves as a pavement base stabilizer, mixed with asphalt and cement to improve the compressive strength, water resistance and frost resistance of roads.

Equipment for Processing Dolomite Powder

The core of dolomite powder processing is a two-stage process of crushing, pretreatment + milling and classification. Dolomite, a medium-soft non-metallic mineral with a Mohs hardness of 3.5~4, features non-stickiness and low moisture content, making it compatible with most non-metallic mineral milling equipment. Different finished product fineness (conventional powder/ultra-fine powder) corresponds to different core milling machines, while the pre-stage crushing equipment is of a general-purpose type. The overall process is simple and highly adaptable. Below is the detailed introduction of core equipment and model selection by process link, which also aligns with the equipment requirements for high-end ultra-fine powder processing:

I. Pre-stage Crushing & Pretreatment Equipment (Indispensable, Pre-process for Milling)

Function: Crush large dolomite lumps (raw ore particle size usually 0.5~3m) to the feed requirement of milling machines (≤30mm) to improve the efficiency of the subsequent milling process. All are general-purpose crushing equipment for non-metallic minerals:

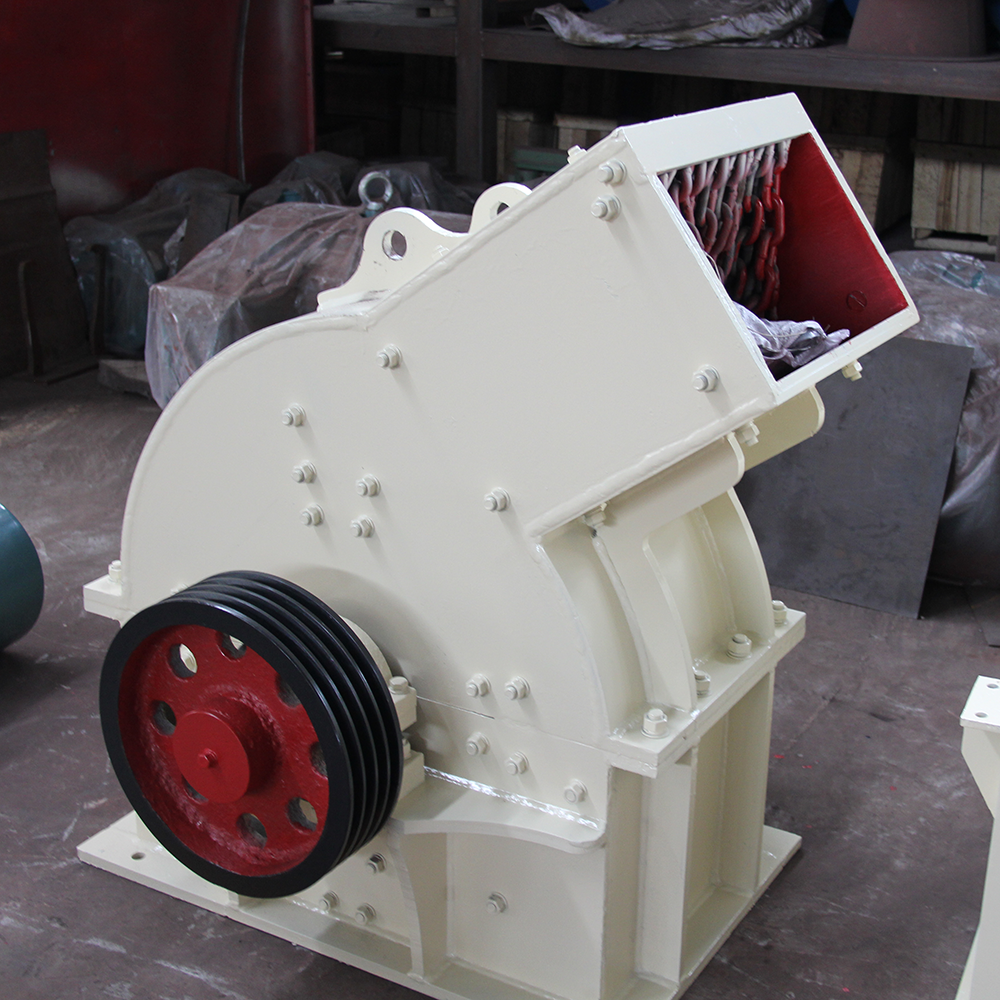

- Jaw Crusher: Core equipment for primary crushing, crushing large raw ore lumps to 100~300mm, suitable for all dolomite milling production lines.

- Impact Crusher/Cone Crusher: Supplementary for secondary crushing, further crushing the primary-crushed stone to ≤30mm with uniform finished particle size and no over-crushing, improving the efficiency of subsequent milling;

- Supporting equipment: Vibrating Feeder and Belt Conveyor, realizing uniform feeding and continuous conveying of raw materials.

Depending on the different production capacity requirements, the costs of the pre-stage crushing part also vary. The main factors to be considered include the following points:4

- What are the materials that we need to process? Is it a hard stone or a soft stone?

- What is the maximum particle size of our raw materials? If the particles of the raw materials are relatively large, then we might need to carry out a secondary grinding process.

- What is the granularity of the product we are requesting? Because different types of crushers have a maximum crushing ratio, we generally consider a crushing ratio of 1:8 or less to be very reasonable.

Generally, we consider that the cost of a stone crushing line with a production capacity of 100 tons per hour is approximately 200,000 RMB. This is a normal and reasonable price estimate.

II. Core Milling & Classification Equipment (Determine Dolomite Powder Fineness/Quality, Selected by Demand)

It is the key to dolomite powder processing, with fineness as the core basis for model selection. Conventional powder focuses on cost performance, while ultra-fine powder centers on high-value-added processing. Both types of equipment are fully matched with the mineral characteristics of dolomite:

1. Suitable for 80~400 mesh conventional dolomite powder (mainstream demand for building materials, metallurgy, agriculture, and other fields)

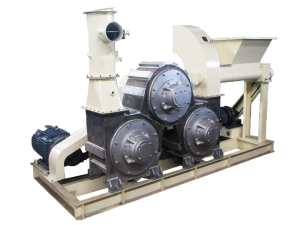

pendulum mill

Currently, Cronus Company offers 8 different models of the Pendulum Mill. Starting from the smallest model, 4R3220, to the largest model, CRRM2500, the fineness of the processed stone ranges from 40 to 400 mesh, and the production capacity ranges from 2TPH to 30TPH.

The cost of a pendulum mill:

Depending on the different models, the quotation for our company’s pendulum mill ranges from 40,000 USD to 25,0000 USD.

The Pendulum Roller Mill (Raymond Mill) is the core, including classic Raymond Mill, improved European version mill and vertical pendulum mill, which is the mainstream choice for this fineness range:

- Advantages: Moderate capacity (0.3~20t/h), low equipment cost, easy operation and maintenance, high milling efficiency; it can directly produce uniformly sized 80~400 mesh powder with a built-in classifier, eliminating the need for additional classification equipment.

- Applicable scenarios: Large-scale industrial production for conventional applications of dolomite powder, with the highest cost performance.

2. Suitable for 600~2500 mesh and above ultra-fine dolomite powder (high value-added for rubber and plastic fillers, high-end coatings, daily chemicals and other fields)

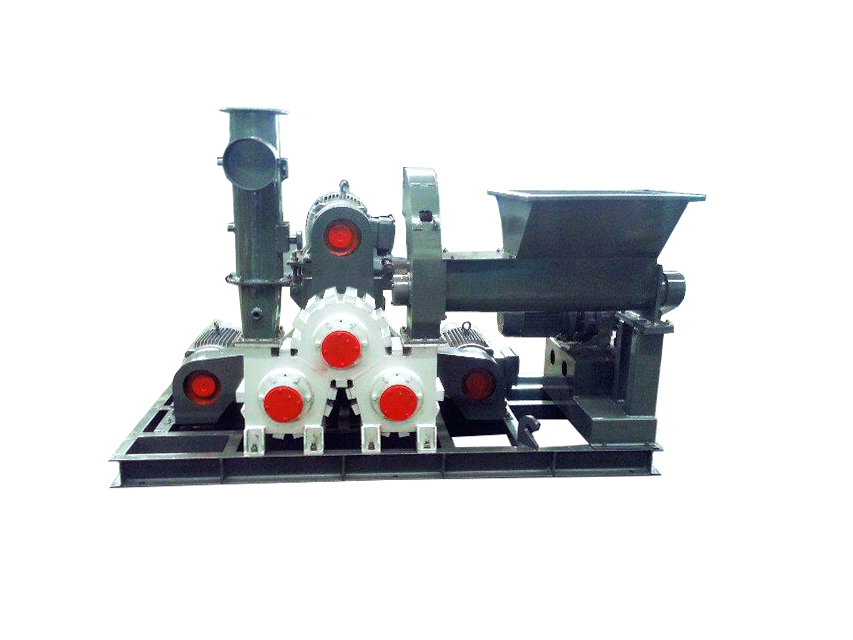

ultrafine grinding mill

The Ultra-fine Mill is the core, and also the key adapted equipment of your company’s Cronus brand:

- Advantages: Equipped with a high-precision classification system with far higher classification accuracy than conventional milling machines, which can precisely control the powder particle size (no oversized coarse powder). In addition, the dolomite powder processed has excellent whiteness retention and good powder fluidity during the milling process, perfectly matching scenarios with high requirements for powder quality, such as rubber and plastic fillers and high-end coatings.

- Applicable scenarios: High-end processing of ultra-fine dolomite powder, the core equipment to improve product added value.

Currently, Cronus Company offers three models of ultrafine grinding mills, namely: CRGM80, CRGM100, and CRGM125.

The price of the ultrafine grinding mill is as follows:

CRGM80: 38000 USD-50000 USD(You can choose variable frequency control or brand motors such as Siemens motors.)

CRGM100: 50000 USD-65000 USD(You can choose variable frequency control or brand motors such as Siemens motors.)

CRGM125: 11,0000 USD-15,0000 USD(You can choose variable frequency control or brand motors such as Siemens motors.)

III. Supporting Auxiliary Equipment (Indispensable for Milling Lines, Ensuring Continuous Production & Environmental Protection)

stone powder coating machine

elevator for

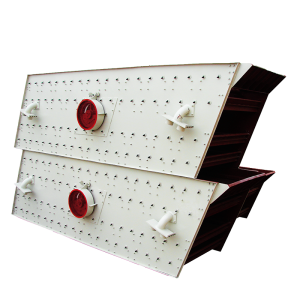

vibrating screen

All dolomite milling lines need to be equipped with such equipment, which links with the core milling machine to form a complete production line:

- Classifier: Built-in/external, precisely controlling the fineness of finished products; the classification system accuracy of ultra-fine mills is a core configuration.

- Collection system: Cyclone Collector (main collection) + Pulse Bag Filter (fine collection + tail gas purification), with a powder collection rate of ≥99%, meeting environmental emission requirements;

- High-pressure Fan: Providing power for airflow conveying to realize the airflow circulation of “milling – classification – powder collection”;

- Electric Control System: Realizing centralized control and automatic continuous production of the milling line, reducing manual operation.

Core Model Selection Summary of Dolomite Powder Processing Equipment

| Finished Product Fineness | Core Milling Equipment | Adapted Application Fields | Core Advantages |

|---|---|---|---|

| 80~400 mesh | Pendulum Roller Mill (Raymond Mill/European Version Mill/Vertical Pendulum Mill) | Building materials, metallurgy, agriculture, and the conventional chemical industry | High cost performance, easy operation, suitable for large-scale production |

| 600~2500 mesh and above | Ultra-fine Mill (Cronus Ultra-fine Mill) | Rubber & plastic fillers, high-end coatings, daily chemicals, and high-end papermaking | High classification accuracy, superior powder quality, high added value |

Overall, the mineral characteristics of dolomite mean no custom-made equipment is required for its processing. Pendulum Roller Mills are sufficient to meet the mainstream demand for conventional powder processing, while ultra-fine mills are the core application scenario for ultra-fine dolomite powder processing, also the key direction to increase profits in dolomite powder processing.