Customer Basic Information Introduction:

This client is the largest provider of light-burned magnesium oxide powder in the Gansu region. It is expected to produce 4,000 tons of 800-mesh light-burned magnesium oxide powder per month. The client holds a technical patent for the pre-processing technology of light-burned magnesium oxide and the produced magnesium oxide powder has high activity, controllable reaction time and fine particle size, which is highly favored by customers. Currently, the company’s production capacity of magnesium oxide falls far short of meeting market demand, and it needs to continuously upgrade its production line equipment.

After extensive communication, the client learned that our company’s ultra-fine grinding machine has unique advantages in the field of light-burning magnesium oxide, so they chose to cooperate with us.

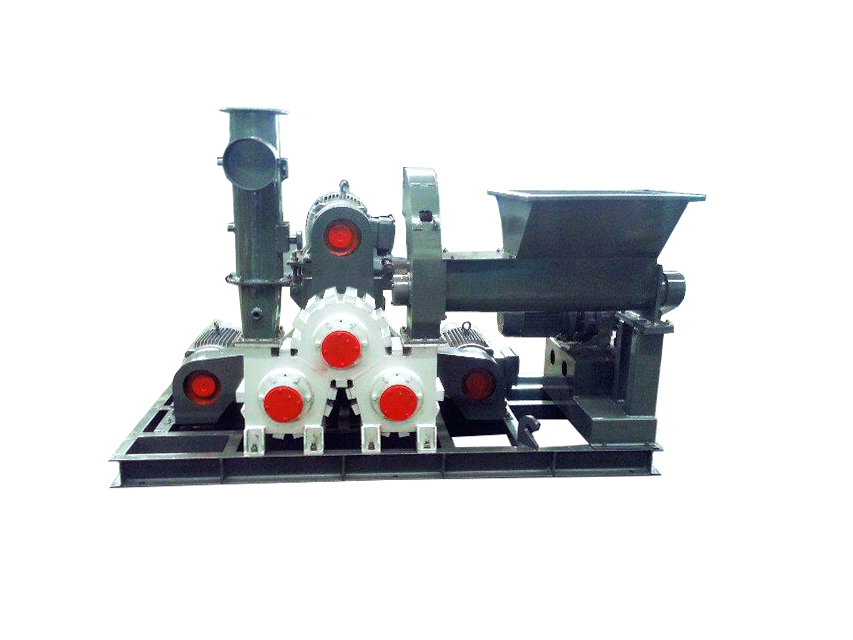

Light-fired Magnesium Oxide Ultrafine Grinding Machine Equipment

Light-fired Magnesium Oxide Ultrafine Grinding Machine

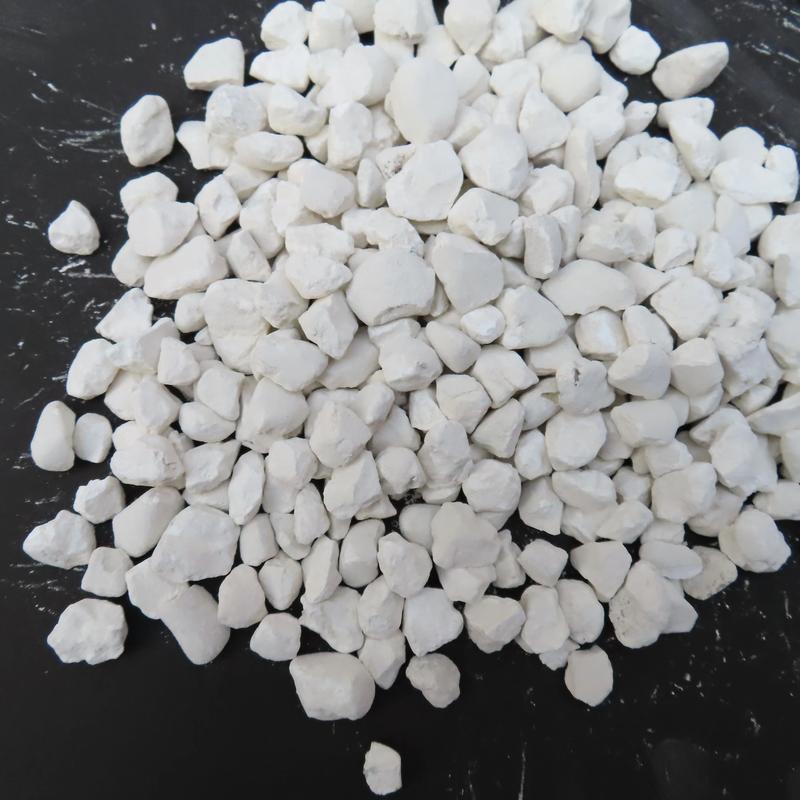

materials: Light-fired Magnesium Oxide

Fineness: 800 mesh D97

Grinding Mill Model: cronus CRGM125

Capacity: 5 t/h

The Cronus 125 model magnesium oxide grinding machine is the largest ultra-fine grinding machine of our company. This machine is equipped with a powerful 200kw motor, a 132kw fan and a 75kw analyzer. The strong power ensures that the main unit of the grinding machine has the ability to work efficiently. Due to the relatively high viscosity of magnesium hydroxide, it is prone to clogging the pipelines and adhering to the grinding rollers of the grinding machine, resulting in increased main current, reduced feed volume, and other situations. Our company has increased the multi-screw conveyor according to the actual needs of customers, and also equipped it with a higher power frequency converter, which can be adjusted in real time according to the processing load of the main unit. This ensures that the equipment is in the optimal working state of stable feeding, stable grinding, and stable output.

The Cronus ultra-fine grinding mill is not only used for processing micro-powder in the magnesium oxide industry, but also can be applied to grinding non-metallic materials such as calcite, limestone, marble, wollastonite, paraffin stone, talc, and carbon black. The processing effect is superior to that of magnesium oxide. After testing, the output of processing 800-mesh calcium carbonate can reach as high as 16 tons.

The entire installation process of the Cronus magnesium oxide grinding machine

This video documents the entire process from the installation and commissioning of the magnesium oxide equipment to the normal start-up and operation of the entire production line by the customer. Our technical staff are always on site, promptly answering customers’ questions and providing full guidance throughout the critical installation process of the equipment.

Applications of Light Burned Magnesium Oxide (LBO)

Light Burned Magnesium Oxide is a high-activity product made by calcining magnesite and other magnesium-based raw materials at 700–1000℃. With its robust chemical reactivity, it delivers exceptional performance across diverse industrial and agricultural sectors, as outlined below:

1. Building Materials (Core Application)

- Serves as the key raw material for magnesite cement (magnesium oxychloride cement), ideal for manufacturing fireproof boards, magnesium oxide boards, ventilation ducts, manhole covers and decorative profiles—thanks to its fast setting, high strength and fire resistance.

- Acts as an additive in thermal insulation mortar and blocks, boosting thermal insulation, bonding strength, water resistance and crack resistance.

2. Refractory Materials

- Blends with alumina, silica and other refractory ingredients to produce medium-and low-temperature refractory products, applied in industrial kiln linings, flue refractory layers, steelmaking and non-ferrous metal smelting.

- Functions as a binder for refractory castables, enhancing workability and high-temperature stability.

3. Chemical Industry

- Reinforcing agent and filler for rubber and plastic products (tires, seals, etc.), improving tensile strength, wear resistance and heat resistance while cutting production costs.

- High-efficiency wastewater treatment agent: neutralizes acidic wastewater, and its hydrolyzed magnesium hydroxide colloid adsorbs heavy metals (Pb, Cd, Hg) and fluoride ions.

- Raw material for producing magnesium sulfate, magnesium carbonate and other magnesium salts, which are widely used in agriculture, medicine and food industries.

4. Agriculture

- Soil conditioner for acidic soils: adjusts pH value, supplements magnesium (a core component of chlorophyll) and promotes crop photosynthesis, especially suitable for magnesium-demanding crops like citrus, tobacco and vegetables.

- Fertilizer additive for compound fertilizer production, improving nutrient utilization rate.

5. Other Special Uses

- Alternative to lime/limestone for flue gas desulfurization in power plants and steel mills, featuring high desulfurization efficiency and recyclable by-products.

- Filler and sizing agent for paper, enhancing whiteness, opacity and printability.

The main grinding equipment recommended by Cronus:

What are the differences between Raymond grinding machine, ultrafine grinding machine and ultrafine vertical mill?