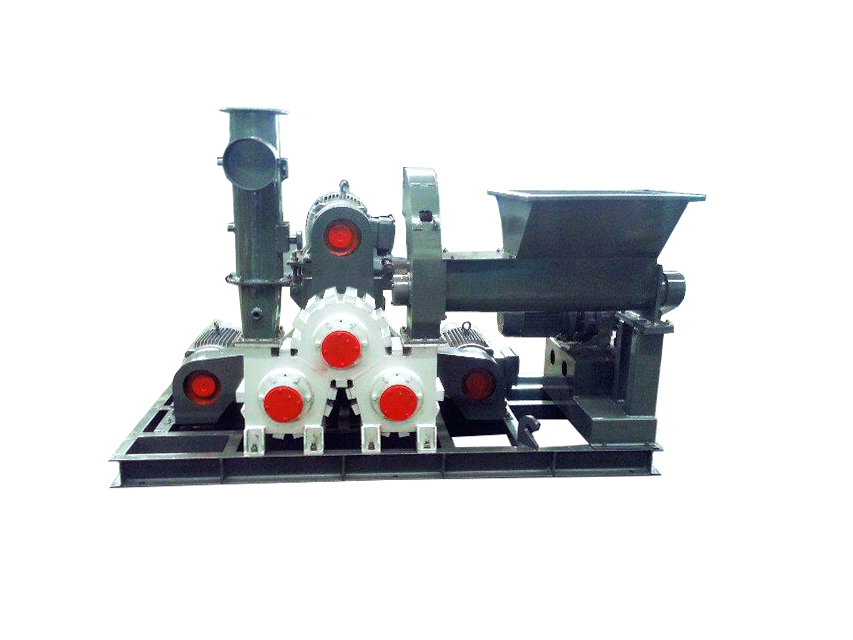

Cronus RCB (Recycled Carbon Black) production line special grinding mill

What are the uses of dolomite powder? Dolomite Powder Manufacturing Plant Cost Dolomite powder is a calcium-magnesium double carbonate powder (main component: CaMg(CO₃)₂) processed from dolomite through crushing and milling (by pendulum roller mills, ultra-fine mills and other equipment). Classified by fineness into ordinary powder (80-400 mesh) and ultra-fine powder...

What is stone paper? how to process paper-grade calcium carbonate? Stone Paper (also known as inorganic powder-based eco-friendly stone paper, synthetic paper, or mineral paper) is a novel, environmentally friendly material that falls between paper and plastic. It is made primarily from calcium carbonate – ultra-fine powder derived from limestone...

Customer Basic Information Introduction: This client is the largest provider of light-burned magnesium oxide powder in the Gansu region. It is expected to produce 4,000 tons of 800-mesh light-burned magnesium oxide powder per month. The client holds a technical patent for the pre-processing technology of light-burned magnesium oxide and the...

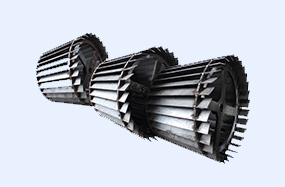

The Raymond grinding mill is one of the common equipment in the grinding production line. Due to its efficient and energy-saving features, it has won the favor of a large number of users. It can process various mineral materials quickly and with high quality, which is inseparable from its precisely...

The fineness of the grinding powder indicates the size of the finished product particles after the material is ground by the Raymond grinding machine. As one of the parameters for users to select a Raymond grinding machine, the question arises: During the operation of the equipment, which factors will affect...

Bearings are an important component in the Raymond grinding machine, and they are also one of the parts that are prone to wear in the machine. Frequent replacement of the grinding machine bearings not only seriously affects the production progress of the enterprise but also increases the maintenance costs of...

In industrial production, the Raymond mill serves as a crucial grinding equipment and is widely used in various fields such as mining, metallurgy, and building materials. The performance of the mill directly impacts production efficiency and product quality. Therefore, when purchasing a Raymond mill, it is essential to pay close...

The Raymond mill is a commonly used ultra-fine grinding equipment for processing ore into powder. This equipment crushes materials through the grinding rollers pressing against the grinding ring, achieving the desired fineness and output with the combined action of a fan and an analyzer. The entire Raymond mill system adopts...