What is stone paper? how to process paper-grade calcium carbonate?

Stone Paper (also known as inorganic powder-based eco-friendly stone paper, synthetic paper, or mineral paper) is a novel, environmentally friendly material that falls between paper and plastic. It is made primarily from calcium carbonate – ultra-fine powder derived from limestone or marble, accounting for about 70-80% of the composition. Additional components include high-molecular polymers such as HDPE/PP (about 15-20%) and a small amount of additives. This material is produced through a special process that does not require wood, water, or strong chemical agents, thus revolutionizing the traditional paper-making methodology.

What are the raw materials for stone paper?

| ingredient | proportion | functon | source |

|---|---|---|---|

| caco3 powder | 70-80% | The main raw materials determine the whiteness, stiffness and environmental protection attributes | Limestone, marble deposits, or industrial calcium carbonate waste |

| high-molecular polymer | 15-20% | Adhesive, endowing formability and flexibility | HDPE (High-Density Polyethylene) or PP (Polypropylene) |

| accessory ingredient | 2-5% | Functions such as dispersion, toughening and antioxidation | Dispersants, coupling agents, plasticizers, etc |

Production Process Flow (Four Core Steps)

- Ore Pretreatment: Limestone is crushed → ultra-fine grinding (to d97 ≤ 10μm; in high-end cases, to sub-micron level) → purification (whiteness ≥ 90)

- Composite Modification: Calcium carbonate powder + polymers + additives → high-speed mixing → activation and modification → granulation (to produce masterbatches)

- Molding and Processing: The masterbatches are extruded → blow-molded/rolled → stretched → shaped → resulting in films/plates

- Post-treatment: Cutting, printing, die-cutting, etc., to produce the final product.

Process advantages: The entire process is conducted without water, strong acids or bases, or bleaching agents. Emissions of waste gas, wastewater, and solid waste are virtually zero. Energy consumption is only 30-40% of that in traditional papermaking.

The equipment used in this production process-how to process paper-grade calcium carbonate?

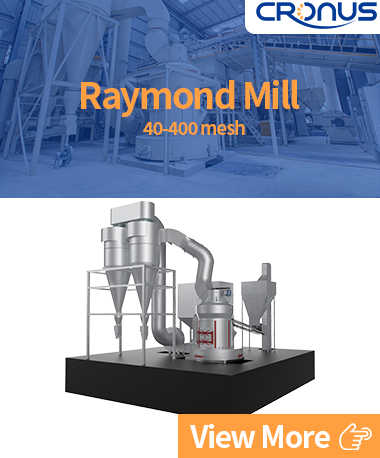

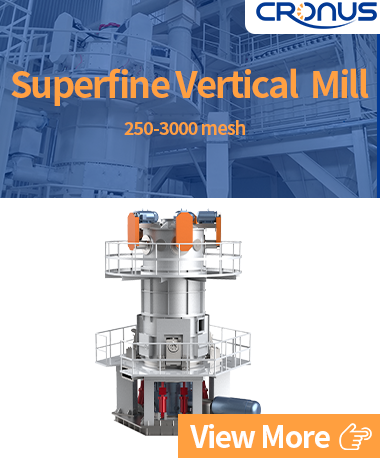

Base information of ultrafine grinding mill

Product Name: ultrafine grinding mill

Fineness:300 mesh-3000 mesh 47-5um

Capacity:1-20 TPH(different models and different fineness)

Models: CRGM80,CRGM100,CRGM125

Apply to:Marble, limestone, calcite, talc, pyrophyllite, dolomite, carbon black, etc.

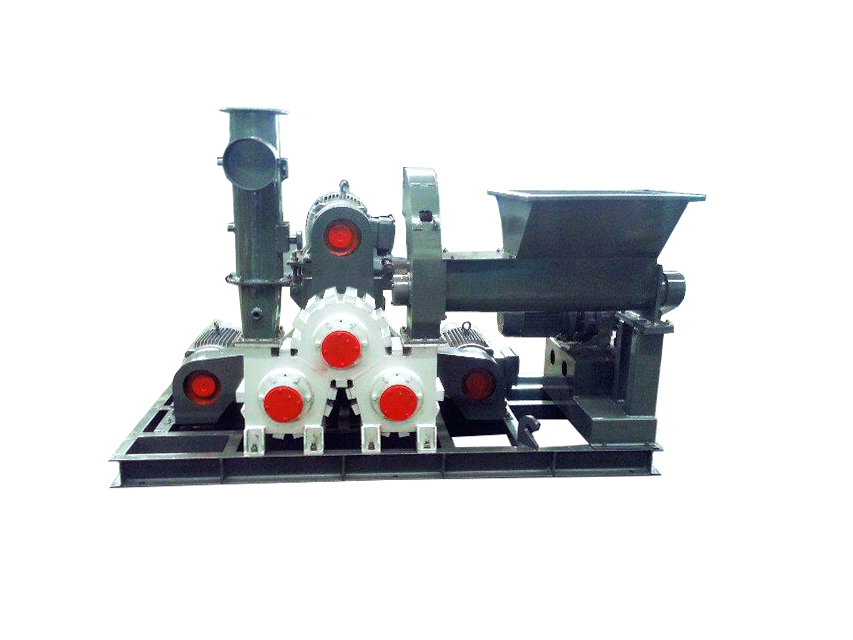

stone powder coating machine

Base information of stone powder coating machine

The stone powder modifier (also commonly referred to as powder modifier/calcium carbonate surface modifier) is a vital supporting equipment in the production of stone paper and the deep processing of non-metallic minerals. Its primary function is to perform surface activation and modification on inorganic stone powders such as calcium carbonate. Through physical and chemical methods, the surface properties of the stone powder are altered, thereby addressing the compatibility issues between inorganic stone powders and organic polymer materials like PE/PP. As a result, the modified stone powder exhibits improved dispersibility, adhesion, and fill volume in composite materials. This equipment is essential for ensuring the quality of products such as stone paper and plastic fillers.

Technical standard requirements for paper-grade calcium carbonate in the stone papermaking process

In the stone-based papermaking process, the core technical specifications for paper-grade calcium carbonate focus on key indicators such as purity, whiteness, particle size distribution, abrasion resistance, and dispersibility. Additionally, the material must comply with industry standards (e.g., QB/T 2811-2019) and production requirements to ensure the mechanical properties, surface quality, and production stability of the final paper. The detailed requirements are as follows:

I. Requirements for Core Technical Indicators

| Indicator Category | Key parameters | Adaptation requirements for stone papermaking | Description |

|---|---|---|---|

| purity | Calcium carbonate content | ≥98% | Reduce the impact of impurities such as silicon, aluminum, and iron on the color of paper and equipment, and avoid defects in production. |

| Hydrochloric acid insoluble matter | ≤0.5% | Reduce wear and tear on grinding equipment and ensure product uniformity | |

| Whiteness | D65 brightness | ≥90,high-end products≥94 | It affects the whiteness of the paper and the printing effect. The higher the whiteness, the more conducive it is to the production of high-value-added products. |

| Particle size distribution | partical size d97 | Ultra-fine filler grade: ≤10μm; Coating grade: 2μm content ≥60% | Excessively coarse particle size can easily lead to rough surface of the formed paper and reduced mechanical properties; excessively fine particle size results in poor dispersibility and a tendency to agglomerate. |

| screen residue | 45μm sieve residue ≤ 0.2%, 125μm sieve fully passed | Avoid large particles causing paper page defects | |

| Abrasion value | Abrasion value of calcium carbonate grinding powder | Filler grade ≤ 20mg/2000 times; coating grade ≤ 7mg/2000 times | Reduce wear and tear on equipment such as extrusion and calendering machines, and extend the service life of the equipment. |

| Dispersibility | oil absorption value | Compatibility with polymer materials (such as PE) | Excessively high oil absorption increases the amount of additives required, thereby affecting the strength of the paper produced. |

| Solid content of paste products | ≥70% | Ensure the stability of granulation, blow molding / calendering processes | |

| Chemical properties | pH | 8.0-10.0 | Avoid excessively high acidity or alkalinity from affecting compatibility with polymer materials and causing corrosion of production equipment. |

| Impurity content | 铁(Fe) | ≤0.05%;锰(Mn)≤0.006% | Prevent impurities from causing the paper to turn gray or yellow in color |

Standards for paper-grade calcium carbonate?

Filler-grade calcium carbonate: Used as the main raw material for stone paper. Generally, it requires d97 = 13-30μm (approximately 500-1250 mesh), whiteness ≥ 90, and abrasion value 8-20mg/2000 times. It is suitable for ordinary packaging paper, writing paper, etc.

Coating-grade calcium carbonate: Used for the surface coating of stone paper. It requires 2μm content of 60-95%, abrasion value ≤ 7mg, and viscosity concentration ≥ 72%, which improves the printability and gloss of the paper.

Common problems and solutions in the stone paper manufacturing process

| Question | Reasons | Optimization measures |

|---|---|---|

| The surface of the finished paper is rough. | The calcium carbonate particles are too coarse or have an uneven distribution. | Ultra-fine ground calcium carbonate is used, and the grinding process is optimized to control particle-size distribution. |

| The equipment wears out quickly. | Excessively high wear values | Choose products with low wear values and control the impurity content. |

| Poor dispersion, agglomeration | The particle size is too fine, or the surface modification is insufficient | Add appropriate dispersants to improve the surface properties of calcium carbonate. |

Other equipment that we can provide