What are the uses of talc powder?

Talc, a naturally occurring hydrous magnesium silicate, is widely used across industries due to its excellent properties—such as lubricity, chemical inertness, heat resistance, and whiteness. Its application is highly dependent on particle size, with 325-mesh (coarser) and 1250-mesh (finer) being two commonly used grades, each suited to distinct scenarios.

1. 325-Mesh Talc: Coarse Grade for Structural and Cost-Effective Uses

325-mesh talc has a relatively large particle size (typically 44 μm or smaller, as per mesh-size standards) and is valued for its ability to enhance structural performance while controlling costs. Its key applications include:

- Plastics Industry: Serves as a cost-effective filler in non-premium plastic products (e.g., polypropylene [PP] injection-molded parts, PVC pipes, and plastic films). It improves the rigidity, dimensional stability, and heat resistance of plastics without significantly compromising processability.

- Rubber Industry: Added to rubber compounds (e.g., automotive rubber hoses, conveyor belts, and general-purpose rubber goods) to reduce raw material costs, increase hardness, and enhance wear resistance. It also acts as a processing aid to prevent rubber from sticking to machinery during mixing and molding.

- Paints and Coatings (Industrial/Architectural): Used in low-gloss industrial coatings, architectural latex paints, and primers. It helps improve the paint’s hiding power, scrub resistance, and adhesion to substrates, while its coarse particles do not affect the basic smoothness of non-high-end coating surfaces.

- Ceramics Industry: Mixed into ceramic bodies (e.g., floor tiles, wall tiles, and sanitary ware) to lower the firing temperature, reduce shrinkage during sintering, and improve the ceramic’s mechanical strength and water resistance.

2. 1250-Mesh Talc: Fine Grade for High-Performance and Aesthetic Uses

1250-mesh talc features a much finer particle size (around 10 μm or smaller), offering superior surface smoothness, dispersibility, and compatibility. It is primarily used in applications requiring high performance or aesthetic quality:

- Plastics Industry (High-End Products): Applied in premium plastics like engineering plastics (e.g., ABS, PC/ABS blends) and thin-walled plastic parts (e.g., electronic device casings, automotive interior trim). Its fine particles disperse uniformly in the plastic matrix, improving surface finish (reducing “fish eyes” or roughness) and maintaining the material’s toughness and impact resistance.

- Cosmetics and Personal Care: A critical ingredient in products like face powders, body powders, blushes, and baby powders. The ultra-fine particles provide a smooth, silky texture that adheres well to the skin without causing irritation, while talc’s oil-absorbing property helps control shine. (Note: Food-grade or cosmetic-grade talc is required here, ensuring freedom from impurities like asbestos.)

- Paints and Coatings (High-Gloss/Industrial Protective): Used in high-gloss decorative paints, automotive topcoats, and industrial protective coatings (e.g., for metal structures). Its fine particle size ensures the coating surface is smooth and glossy, while also enhancing scratch resistance and chemical resistance (e.g., resistance to oils or solvents).

- Paper Industry (Coated Paper): Added to the coating layer of high-quality paper (e.g., magazine paper, glossy packaging paper). It improves the paper’s brightness, printability (ensuring sharp ink adhesion), and smoothness, making the paper suitable for high-resolution printing.

- Pharmaceuticals: Used as an excipient in tablet and capsule formulations. Fine talc acts as a glidant (preventing powder from sticking to tablet presses) and a lubricant (improving the flow of pharmaceutical powders during manufacturing), while its chemical inertness ensures compatibility with active pharmaceutical ingredients (APIs).

In summary, 325-mesh talc is favored for cost-sensitive, structural, or low-to-medium performance applications where particle fineness is not critical, while 1250-mesh talc is tailored for high-aesthetic, high-performance, or precision-focused uses that demand ultra-fine particles and superior surface properties.

Talc powder is a crucial raw material in industrial production, particularly in the food and cosmetics industries. By processing talc into ultra-fine talc powder, more functional expansions can be achieved.

A brief introduction to the talcum powder production line project that the client has launched

located : Guangxi Hezhou

processing materails : talc powder

final finenes:325 mesh and 1250 mesh

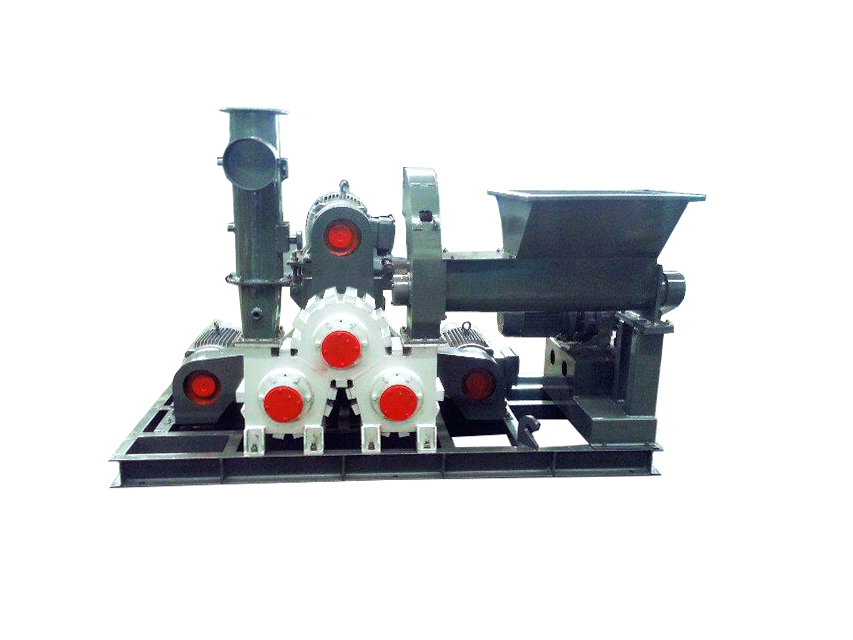

machine: cronus raymond mill and cronus superfine grinidng mill

capacity: 325 mesh talc powder -10TPH 1250 mesh talc powder -8 TPH

This customer is a large-scale supplier of talcum powder in Hezhou City, Guangxi Province. At present, there are a total of 15 talc powder production lines in operation, with an annual production capacity of 10 million tons. The produced mineral powders include talc powder, limestone powder, calcium carbonate powder, etc. The production line we are collaborating with this time is for talc powder. At the initial stage of equipment selection, this client conducted extensive supplier research, also visited and communicated with our company several times, and went to places like Zhengzhou where there are many grinding mill production bases to gain a better understanding. Among many grinding machine suppliers, they chose Shanghai Cronus.