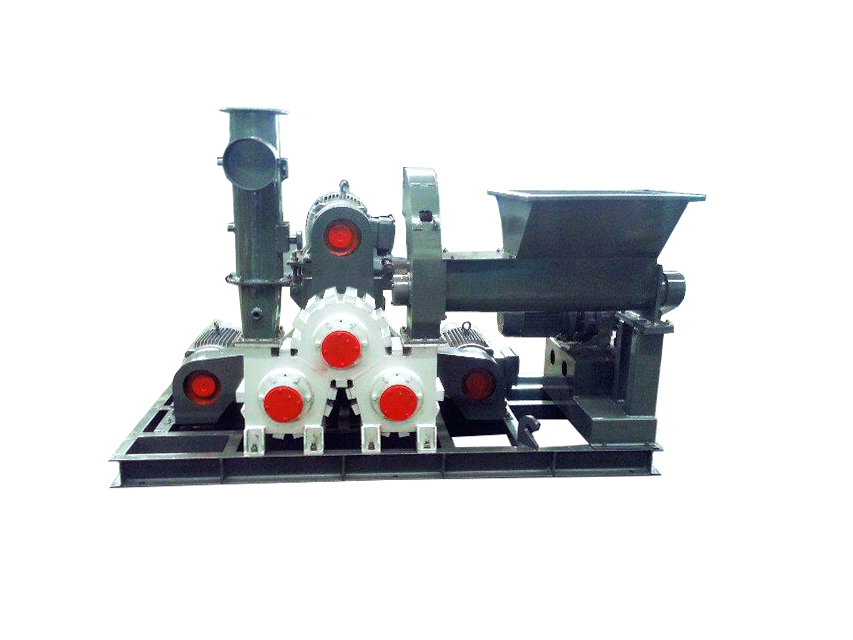

Recently, the four TH bucket elevators and four crushers ordered by our Nigerian client have been completed and are about to be dispatched to Nigeria.

This client ordered four Raymond grinding machines from our company last year. In June this year, due to the need for capacity expansion, they ordered another four Raymond grinding mills from us. These four elevators and crushers are used in conjunction with the Raymond grinding production line. After the equipment is installed, the client’s calcium powder production capacity will reach 1 million tons per year. It is worth noting that this client has only been engaged in the processing of mineral powder for five years, but it has already become the largest supplier of mineral powder in Nigeria, with a very rapid development pace.

This customer has purchased 8 Raymond grinding machines from our company for two consecutive years, demonstrating the comprehensive strength of our products and earning the customer’s recognition of us.

On-site demonstration of the TH bucket elevator

Our other machine:

The Application of TH Bucket Elevator TH bucket elevator is a common vertical conveying equipment, mainly realizing continuous lifting and transportation of materials through the cooperation of the bucket belt and driving device. It has a wide range of applications, which are mainly reflected in the following aspects:

I. Vertical Material Conveying in Industrial Fields

Mining Industry

Used for conveying granular or powdery materials such as ores, mineral powders, and coal. For example, after mining, ores are lifted from low places to crushing equipment or beneficiation workshops to improve the efficiency of material processing. – **Building Materials Industry** Conveys building materials raw materials such as cement, lime, sand, and crushed stones, which are commonly used in cement plants and concrete mixing stations to lift raw materials from storage bins to production equipment for batching and processing.

Chemical Industry

Transports chemical raw materials (such as fertilizers, soda ash, salt, etc.), which can connect different processes in chemical production lines to achieve vertical material transportation, avoiding the tediousness and pollution of manual handling.

II. Grain and Agricultural Product Processing

Grain Storage and Processing** In grain processing plants and granaries, it is used to lift raw grains such as wheat, rice, and corn, as well as finished products like flour and rice. For example, grains are lifted from the bottom of the granary to cleaning equipment or packaging workshops to achieve automated conveying.

Agricultural Product Handling

Conveys oil crops (such as soybeans, peanuts) and feed raw materials (such as soybean meal, corn flour). In feed processing plants, raw materials can be lifted to mixing equipment to complete the proportioning production of feed.

III. Environmental Protection and Waste Treatment

Garbage Disposal

In waste incineration plants or landfills, it conveys sorted garbage fragments and incinerated slag, lifting materials from the bottom of processing equipment to subsequent treatment links (such as screening or transport vehicles). –

Sludge Treatment

Transports sludge generated in the sewage treatment process, lifting it from the sedimentation tank to dewatering equipment or stacking sites, reducing the difficulty of manual operation.

IV. Applications in Other Industries

Metallurgical Industry

Conveys metallurgical powders (such as iron powder, copper powder), sintered ore, etc. In steel plants, sintered ore can be lifted from the sintering machine to the blast furnace charging system. – **Food Processing

Transports granular food raw materials (such as candies, nuts, grains), meeting the hygiene requirements in food production. For example, flour is lifted to mixing equipment in biscuit production lines.

Features and Advantages of TH Bucket Elevator

High conveying efficiency: Capable of continuous operation with stable lifting speed, suitable for vertical transportation of large batches of materials.

Small floor space : The vertical conveying method saves ground space, especially suitable for compact workshop layouts. – **Good sealing performance**: The closed body design reduces material dust and spillage, protecting the environment and the health of operators.

Strong adaptability: Different materials of buckets (such as cast iron, stainless steel) and conveying speeds can be selected according to material characteristics (such as particle size, humidity, density) to meet diversified needs.